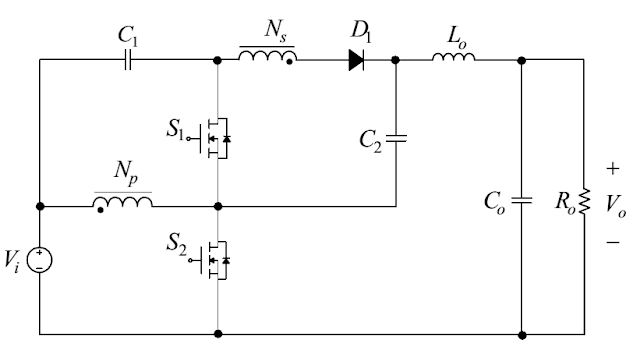

- POWER =60W

- VIN=12V

- VOUT=72V

WAVE FORMS

WAVE FORMS

s2-s1 gate signals

s2-s1 gate signals

output (attenuation of 10 used)

output (attenuation of 10 used)

Vds2

PROGRAM (OPEN LOOP)

//Micro controller -dspic30f2010

//compiler -mikroc

//i have used crystal of 20 MHz

//output at 50KHz

// //duty_50% = (clock_frequency/ (output_frequency*4 *1)) -1 =99

//DEAD TIME = duty_50%/2 =45

void main()

{

unsigned int pwm_period, current_duty ;

current_duty=99; //duty ratio 50% =99

pwm_period = PWM1_MC_Init(50000, 0, 0x11, 0); //enable 1L AND 1H pwm pins

PWM1_MC_Set_Duty (current_duty, 1) ;

PWM1_MC_Start();

DTCON1=10; //DEAD TIME CONTROL maximum 79

while (1);

}

PROGRAM (CLOSED LOOP)

//used crystal of 20 MHz

//output at 50KHz

// //duty_50% = (clock_frequency/ (output_frequency*4 *1)) -1 =99

//DEAD TIME = duty_50%/2 =45

//feed back by 100k and 2.2k

//adc value —295 for 67V

//char g[5];

//void adctoascii (void); //declare globally

int feedbackvoltage;

void main()

{

unsigned int pwm_period, current_duty ;

current_duty=99; //duty ratio 50% =99

pwm_period = PWM1_MC_Init(50000, 0, 0x11, 0); //enable 1L AND 1H pwm pins

PWM1_MC_Set_Duty (current_duty, 1) ;

PWM1_MC_Start();

DTCON1=10; //DEAD TIME CONTROL maximum 79

//UART1_Init(9600); // Initialize UART module at 9600 bps

//Delay_ms(100); // Wait for UART module to stabilize

//UART_Write_Text(“Start”);

//UART_Write(0xd);

TRISB.F0 = 1;

while (1)

{

feedbackvoltage = ADC1_Read(0)*67/295; Delay_ms(10);

//adctoascii ();UART_Write_Text(g);UART_Write(0xd);

//Delay_ms(100);

if(feedbackvoltage>70)

{

current_duty=current_duty-1;

if(current_duty<1)current_duty=0;

PWM1_MC_Set_Duty (current_duty, 1) ;

}

else if (feedbackvoltage<69 )

{

current_duty=current_duty+1;

if(current_duty>160)current_duty=160;

PWM1_MC_Set_Duty (current_duty, 1) ;

}

}

}

Vds2

PROGRAM (OPEN LOOP)

//Micro controller -dspic30f2010

//compiler -mikroc

//i have used crystal of 20 MHz

//output at 50KHz

// //duty_50% = (clock_frequency/ (output_frequency*4 *1)) -1 =99

//DEAD TIME = duty_50%/2 =45

void main()

{

unsigned int pwm_period, current_duty ;

current_duty=99; //duty ratio 50% =99

pwm_period = PWM1_MC_Init(50000, 0, 0x11, 0); //enable 1L AND 1H pwm pins

PWM1_MC_Set_Duty (current_duty, 1) ;

PWM1_MC_Start();

DTCON1=10; //DEAD TIME CONTROL maximum 79

while (1);

}

PROGRAM (CLOSED LOOP)

//used crystal of 20 MHz

//output at 50KHz

// //duty_50% = (clock_frequency/ (output_frequency*4 *1)) -1 =99

//DEAD TIME = duty_50%/2 =45

//feed back by 100k and 2.2k

//adc value —295 for 67V

//char g[5];

//void adctoascii (void); //declare globally

int feedbackvoltage;

void main()

{

unsigned int pwm_period, current_duty ;

current_duty=99; //duty ratio 50% =99

pwm_period = PWM1_MC_Init(50000, 0, 0x11, 0); //enable 1L AND 1H pwm pins

PWM1_MC_Set_Duty (current_duty, 1) ;

PWM1_MC_Start();

DTCON1=10; //DEAD TIME CONTROL maximum 79

//UART1_Init(9600); // Initialize UART module at 9600 bps

//Delay_ms(100); // Wait for UART module to stabilize

//UART_Write_Text(“Start”);

//UART_Write(0xd);

TRISB.F0 = 1;

while (1)

{

feedbackvoltage = ADC1_Read(0)*67/295; Delay_ms(10);

//adctoascii ();UART_Write_Text(g);UART_Write(0xd);

//Delay_ms(100);

if(feedbackvoltage>70)

{

current_duty=current_duty-1;

if(current_duty<1)current_duty=0;

PWM1_MC_Set_Duty (current_duty, 1) ;

}

else if (feedbackvoltage<69 )

{

current_duty=current_duty+1;

if(current_duty>160)current_duty=160;

PWM1_MC_Set_Duty (current_duty, 1) ;

}

}

}